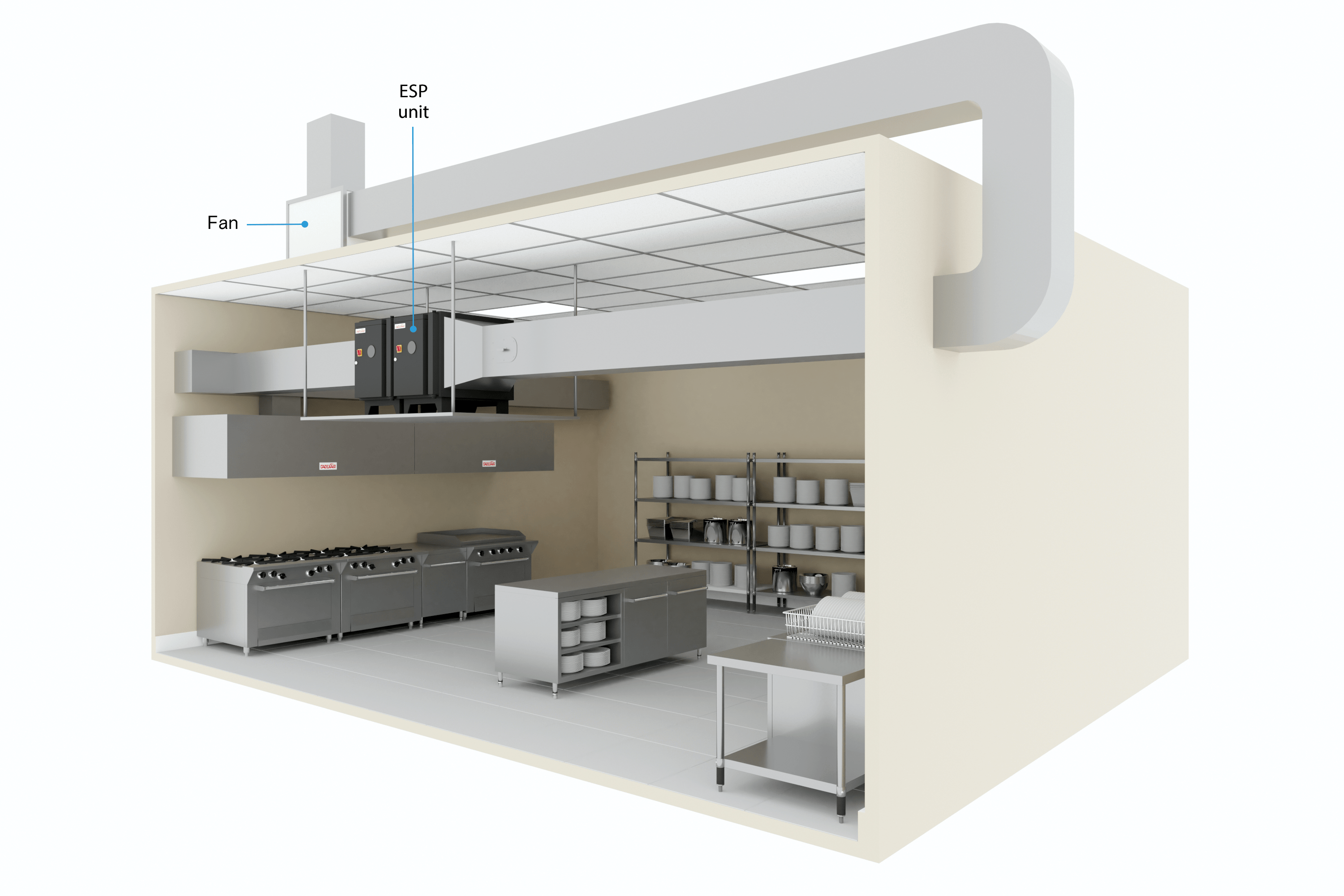

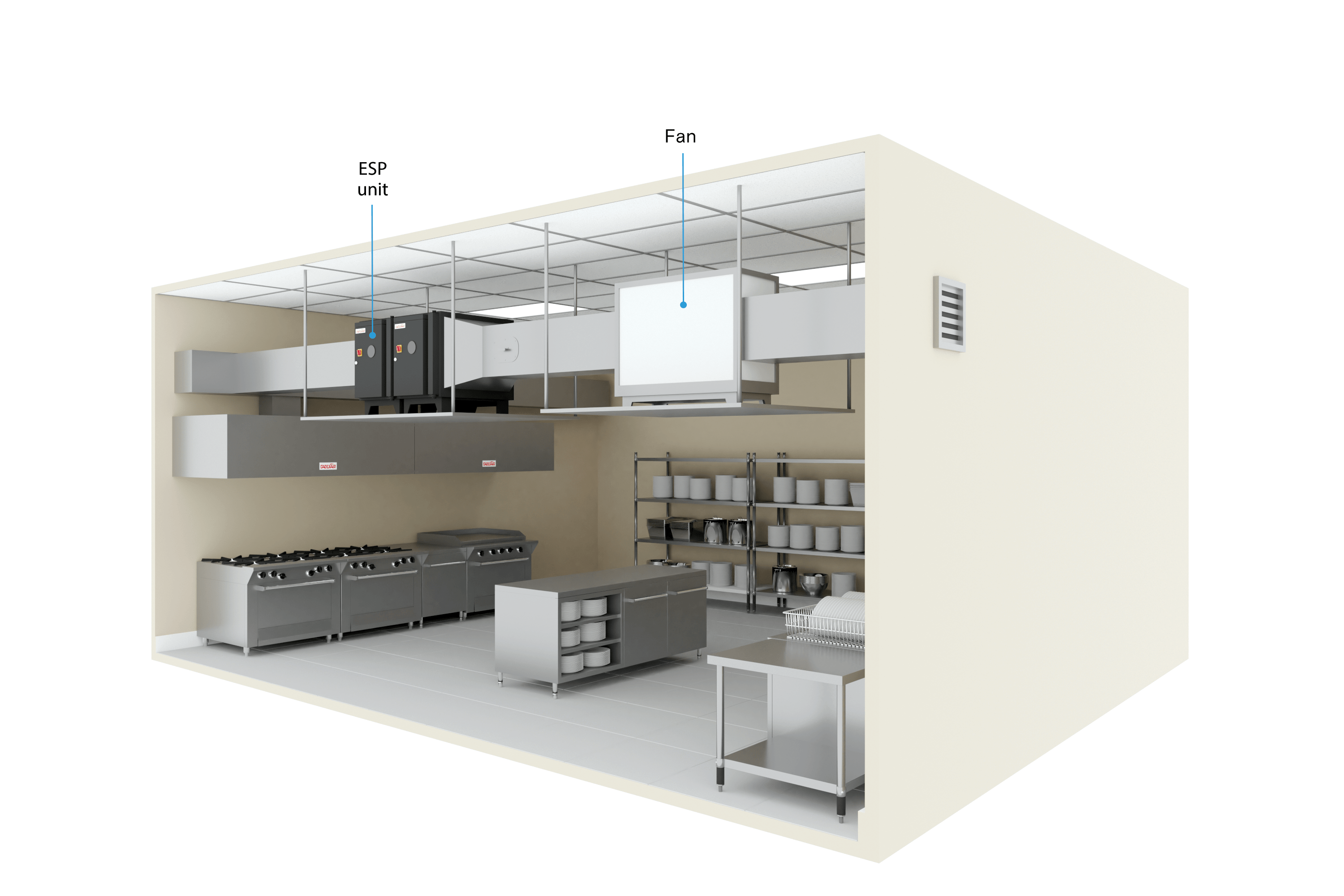

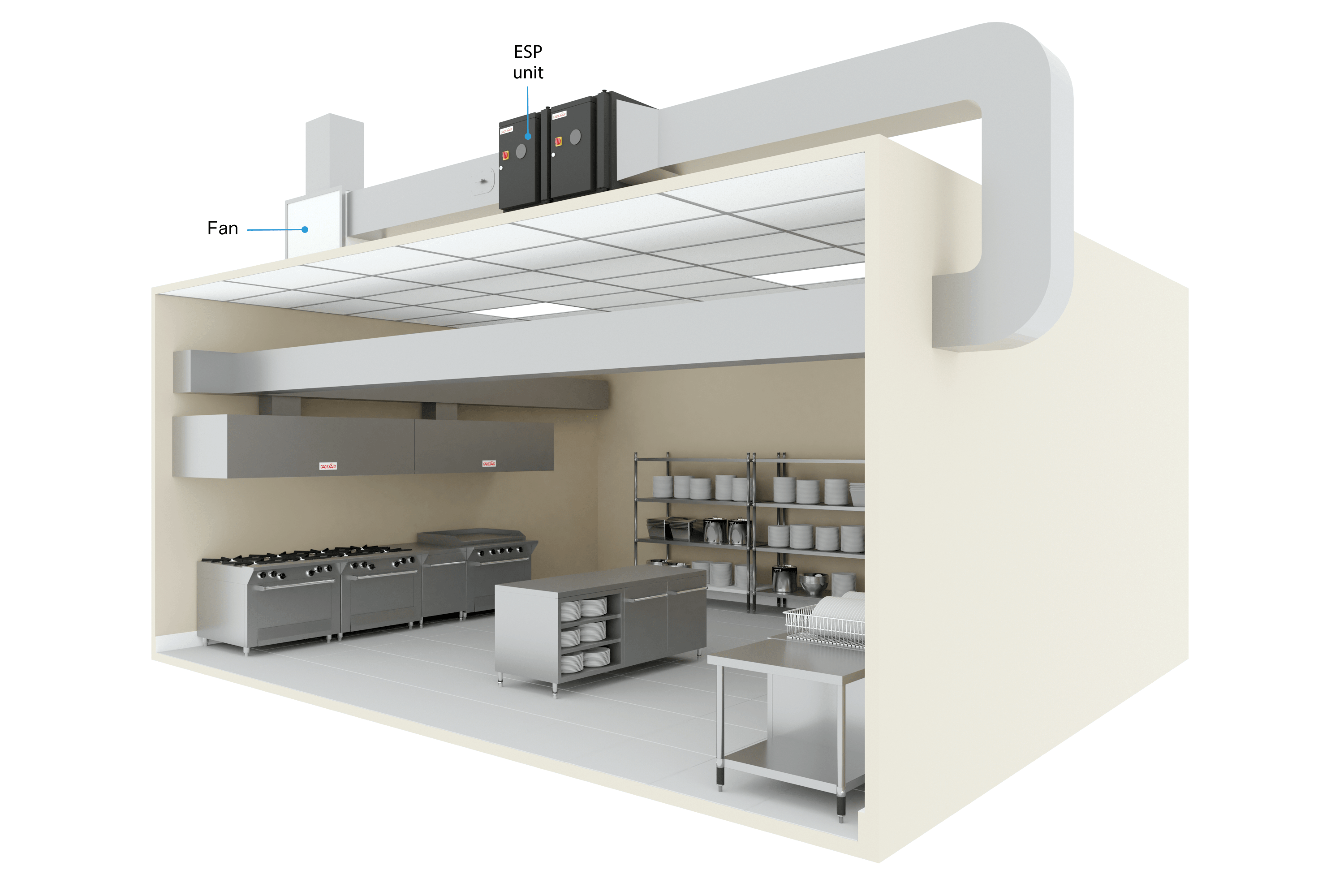

Specifically designed for commercial kitchens

Electrostatic filtration is recommended for kitchens in busy neighborhoods, high-rise condominiums, office buildings, food courts and any space where smoke or poor restaurant air quality can become a nuisance. Furthermore, this type of filtration system is designed to lower maintenance costs thanks to its washable filters. In brief, this technology is a smart choice to avoid the nuisance associated with cooking fumes.