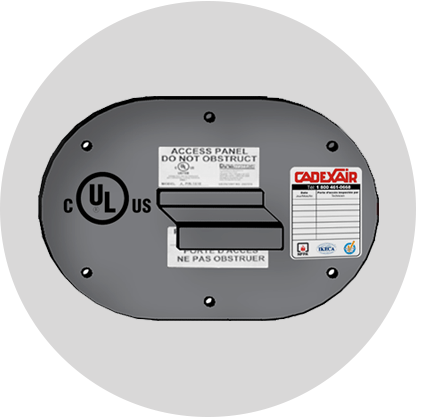

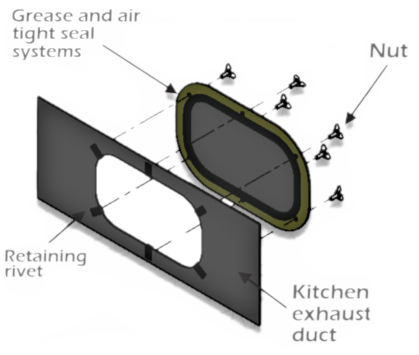

UL ULC doors meet or exceed all NFPA 96 requirements

UL/ULC approved grease duct access doors are the perfect solution to allow proper cleaning of commercial hood ducts.

The advantage of installing access doors at the end of the work

The main advantage of UL ULC access doors installed at the end of the work (without any welding), is to ensure compulsory access for the maintenance of the conduits. It is often demonstrated during duct cleaning (by Cadexair IKECA certified cleaning teams), that many doors initially installed are made inaccessible. Lack of space and coordination in HVAC, plumbing, electromechanical and architectural components is a problem in the construction industry. If the installation of access doors is carried out at the start of the project, there is a high probability that the doors will be blocked or simply inaccessible at the end of the project. By installing them at the end of the work, it is ensured that they remain accessible for future inspections and maintenance, as required by NFPA 96.